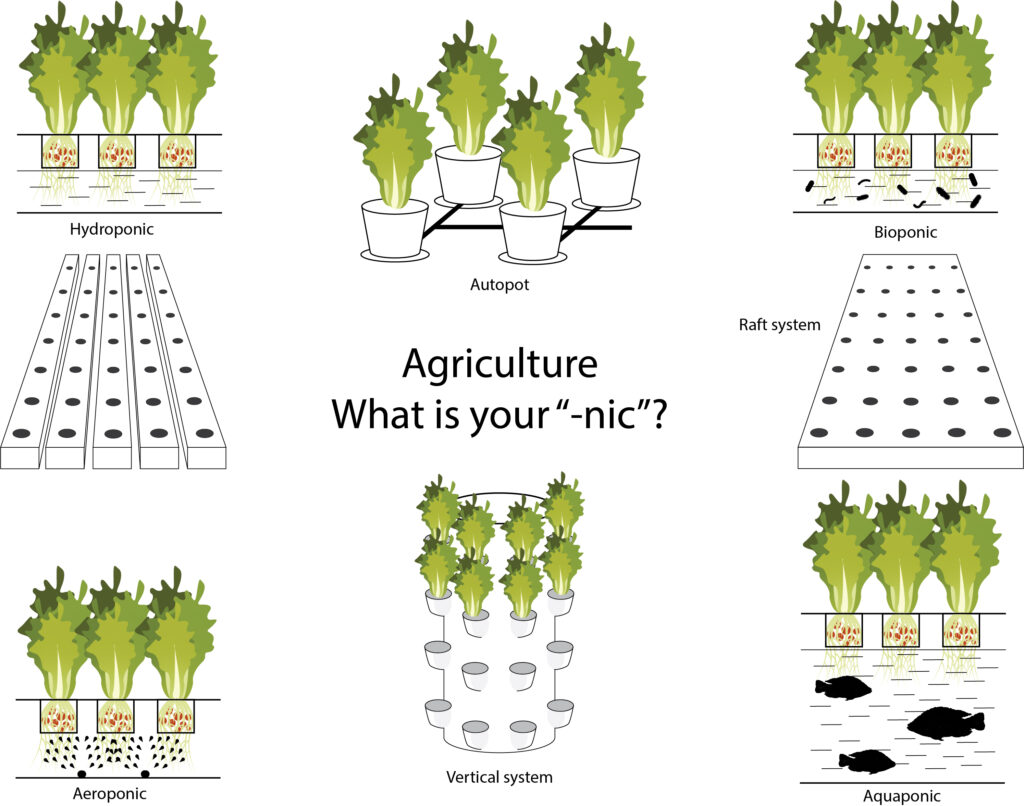

To start small-scale indoor farming, what are your needs? What type of the “-ponic” you need? When it comes to the topic, farming, most people will still have the concept that it is related to soil. However, most of the growers or urban farming will use soilless cultivation for crops such as certain fruits, vegetables, and herbs. It is because studying the soil or ratio of the substrates to be used to cultivate the crops can be tedious, and the nutrients in the soil will be diminished over time. It is much more efficient to use a soilless cultivation method for certain fruits, vegetables, and herbs. Common fruits, vegetables, and herbs that are cultivated using soilless cultivation are blueberries, strawberries, peppers, chilies, tomatoes, lettuces, onions, leeks, carrots, zucchinis, anises, corianders, dills, lavenders, parsley, and rosemary. Some of them required extra care while some are commercially produced using soilless cultivation like hydroponic.

The science of hydroponics began with the experiments that study the elementary composition of plants, which have been dated as early as 1600 A.D. The historical records had revealed that plants had been cultivated in soil-free mixtures of sand and gravel much earlier than that. Before we go into the details, let look at the medium used in soilless cultivation. The medium is any substrates that hold the seeds, seedlings, and rooted cuttings. The major consideration for the system is the cost of the medium used. Most of the media is processed or artificial substrates in which natural substrates such as fine sand and coarse gravel are not suitable. This is because the water-holding ability of the fine sand is very minimum, which made it cannot hold much water and air for the plants. The coarse gravel, on the other hand, has large interstitial spaces that can hold a lot of air space and water, but it is not suitable for the system that does not circulate the nutrients to the plants. A perfect medium is designed to hold an even ratio of water to air, to buffer the pH changes over time, flushed and re-wet easily after being dehydrated completely for storage, reusable or biodegradable, inexpensive, easily available from local stores or online, and should be lightweight to ease the work.

Coconut coir is one the media which has a common trade name like Ultrapeat, Cocopeat, and Coco-tek. It is obtained from coconut which is known as coconut husk, which is an ideal medium that offers protection against root diseases and fungus. It is relatively durable as compared to peat moss. One needs to soak the coconut coir before using it and it eventually will expand up to 6 times the size of the original. As compared to other media, it can be brushed off easily from your hands without any residue. Perlite is a great inert substance made from air-puffed glass pellets which nearly as light as air. It offers excellent oxygen retention. However, it is not suitable for making pure perlite substrate as it will be flushed away by the solution in hydroponic easily. It is often mixed with soil and other substrates to retain oxygen in the soil and soil-free mixes. Vermiculite that made from a natural mineral that expands with the application of heat. It is popular hydroponic media for its affordability, lightweight, and sterile. Vermiculite is often mixed with perlite at the ratio of 50:50, but the drawbacks of it are that vermiculite retains too much water which would suffocate the roots of the plants and it is easily flushed off too.

Lightweight expanded clay aggregate (LECA) is an extremely coarse growing medium among all media used in the system. It is sometimes called as Geolite, Grorox, Hydroton. It holds water by its porosity ad surface area. It is the most ideal medium for the system as it keeps the pH neutral and it is reusable. On the other hand, lava rocks (hydrostone) is less ideal as they alter the pH in the long run and leaves heavy sediment that can harm the equipment like blocking the pipe and impair the filter or pump in long term usage. Therefore, it is always suggested to rinse all kinds of substrates before using them in any systems to rinse off any dirt or sediments. Then, the other medium will be rockwool, which is made from molten rock that is spun into the long and glass-like fiber, which is then compressed into the desired shapes such as bricks and cubes. It is widely used as a seed starting medium as it absorbs the water readily and having decent drainage properties. It can be reused by sterilizing it; therefore, its sterility is categorized as one of its advantages that ensure the system freed from pathogens. However, it raises some environmental issues in which there is pollution from the manufacturing process and the dust of the rockwool can be irritating to the skin and in the lungs if inhaled.

Hydroponic is made from two Greek words, mainly hydro, which means water, and ponos that are defined as labor. Hydroponic is the most common soilless cultivation in the agricultural industry. The flowing nutrient solutions are continuously recycling to supplying the nutrients to the root of the plants with the help of the pump. The reason for having cycling water is to allow oxygen dissolved in the solution that is needed by the plant roots. A static solution tends to kill the roots as they suffocate in anaerobic conditions (absence of oxygen). Aeroponic is an advanced version of hydroponic in which it saves much more water as compared to hydroponic. It is considered the most recent technology to be developed in indoor agriculture. Generally, the plants are suspended from the baskets or pots and the essential nutrients will be sprayed onto the plant roots. Besides, plant roots in an aeroponic received a maximum amount of oxygen. Vertical gardening is an application of aeroponic with a cylindrical unit.

In addition, there is another soilless cultivation developed from hydroponic. Aquaponic is a hydroponic that uses a raft system, which is a combination of hydroponic and living organisms, fish. The raft system is an interesting technique of growing vegetables like lettuces that are supported by baskets or pots which fit into the Styrofoam sheet that float upon a bath of solutions. Then, herbivore fish such as tilapia and crawfish are being raised in the solution. Aquaponic acts as an ecosystem where the fish get their nutrients from biomass teas and aquatic organisms such as algae, microbes, and duckweed. The farmers who have aquaponic used less or no artificial nutrient solution in return as the hydroponically grown vegetables get the nutrients from fish waste which function as a water filter and “clean” the water for the fish. This win-win situation is known as Nutri-cycling. Building an aquaponic is much more complicated but the farmers can earn a side income from selling the fish which could be rewarding.

Fish in a hydroponic system is optional. In many cases, microbes are prefered than to use fishes, which is known as bioponic and considered as more healthy. The beneficial microbes are actively involved in biofiltration to improve nutrients uptake for plants. It has an extra benefit in which there is no need to discharge the water (required by hydroponic) as there is no buildup of electrical conductivity in bioponic. Furthermore, there is a relatively new invention to the market here in the US, which is the Autopot. It is a double trays module that equipped with a smart valve which irrigates the plants with nutrient solution automatically on demand. This made it ideal for unsupervised indoor farming. The bonus for having Autopot is that it can use a mixture of different growing media mentioned earlier.

The nutrient solutions in the system should always be optimized to be suitable for the crops. Alternatively, premix or commercial solutions containing macronutrients and micronutrients (trace elements) together with acids and alkali solution for pH correction. Commonly, the elements for macronutrients are nitrogen (N), phosphorus (P), and potassium (K). Whereas, micronutrients or trace elements that required in little amount are made of calcium (Ca), sulfur (S), iron (Fe), magnesium (Mg), boron (B), manganese (Mn), zinc (Zn), molybdenum (Mo), copper (Cu), and cobalt (Co). The label on the commercial solution for hydroponic or aeroponic is commonly written as 10-10-10, for example. This ratio is represented by N-P-K, which indicates that this solution consists of 10% N, 10% P, and 10% K that sum up to 30% while the rest of the 70% is made of other nutrients. Generally, the optimal pH range for most plants is about 6.0 – 7.0 where all the nutrient salts are neutral within the range. The pH is always monitored with the pH sensor. pH is the key to maintain plant health, growth, and development in all cases.

Since there will be fluctuations in the sunlight received by the plants due to the seasons and weather, growing the plants in indoor conditions with artificial light is performing better than outdoor. Normal fluorescence light is known to be less effective in terms of cost as it is not monochromatic (diverse light) and it produces much heat as compared to light-emitting diodes (LEDs). This indicates that some of the electrical energy had turned into heat which increases the room temperature indirectly. Thus, there is a need to have temperature control by having the setting of lower temperatures using a cooler or air conditioner. Light is a “chemistry” that is needed to be studied according to the species we cultivate. For example, grow light available at the market is designed for low-light plants where limited results are expected. Alternatively, high-intensity discharge (HID) lighting is used in large-scale production of soilless cultivation due to its efficiency in providing the maximum output of photosynthetically active radiation (PAR). For home growers, LEDs are the best option that projects monochromatic lights and cost-effective in the long run.

These systems are required to have a “spring cleaning” to clean it thoroughly to prevent the build-up of algae, bacteria, and mold that present in the nutrient-rich solution. Some cleaning agents specifically designed for soilless cultivation systems or one can use a bleaching agent which is cost-effective. However, the residue of the cleaning agents must be rinsed or flushed off thoroughly before reusing it again. This is because the residue of the cleaning agent may bleach and damage the plants and pump chemically. To start as a home grower, one may need not to empty a room for the hydroponic as there are a lot of sizes of hydroponic systems available. Commercially, the hydroponics system for home growers has been customized into different sizes such as three tiers of the hydroponic system with LEDs. The end users can manipulate the spectrum of the LEDs based on the requirement of the photoperiod and spectrum needed by the plants. Hydroponic is still the most preferred system over other soilless cultivation systems as it is much user friendly.

It is vital to have backup electricity for all soilless cultivation system. This is because a stagnant solution in a hydroponic system for a long period made the system a waterlogged condition. Plant roots will suffocate for the absence of dissolved oxygen in the solution which eventually leads to root rots and death of the plants. Aeroponic, on the other hand, faced no issue on waterlogged conditions as the nutrient solution is sprayed to the roots and the roots get the maximum oxygen in the air. However, a shortage of electricity or malfunction of the sprayers may cause the roots to undergo dehydration. The roots will be dried up instantly within a short period and the plants will wilt and die. The plants that are grown using soilless cultivation contain a higher water content (larger fresh weight). Hence, the drawback is that it is easy to dehydrate as compared to soil-grown plants. It must be cooked or eaten immediately or packed in a nice container to avoid water loss.

Indoor soilless cultivation with an artificial lighting system is a great alternative to conventional farming for vegetables and herbs as well as certain fruits. Because it can be cultivated in hydroponic with optimized solutions and stacked in multiple levels of rack that saved a lot of horizontal spaces. Most recently, the internet of things (IoT) is coming together with these soilless cultivation systems whereby the users can get the alert through the smartphone and fix the issues instantly. Users can control the growth of the plants remotely via their phones. With the presence of a global pandemic by Covid19, the hydroponic system has marked as a remarkably need for almost every household to grow their own food.

Further reading:

Resh, H. M. (1995). Hydroponic food production. A definitive guidebook of soilless food-growing methods (No. Ed. 5). Woodbridge press publishing company.

Resh, H. M. (2012). Hydroponic food production: a definitive guidebook for the advanced home gardener and the commercial hydroponic grower. CRC Press.