The genus Arachis, under the family Fabaceae, consists of 69 species described in the genus and 9 infrageneric taxonomic sections. Only one member of this genus of 20-odd species of annual and perennial legumes from South America is cultivated. It is a very important food crop throughout the tropics and subtropics. All species of this genus are unusual when compared to other legumes as they produce their fruit below the ground.

The peanut (Arachis hypogaea) is an important crop plant, though rarely grown in domestic gardens. This genus is native to South America. It is believed that the peanut is originated from Gran Panatanal region of South America. The largest producer of peanuts is China, followed by India, Nigeria and then the United States. Although treated as nuts, peanuts are more properly pulses that are eaten or processed after drying.

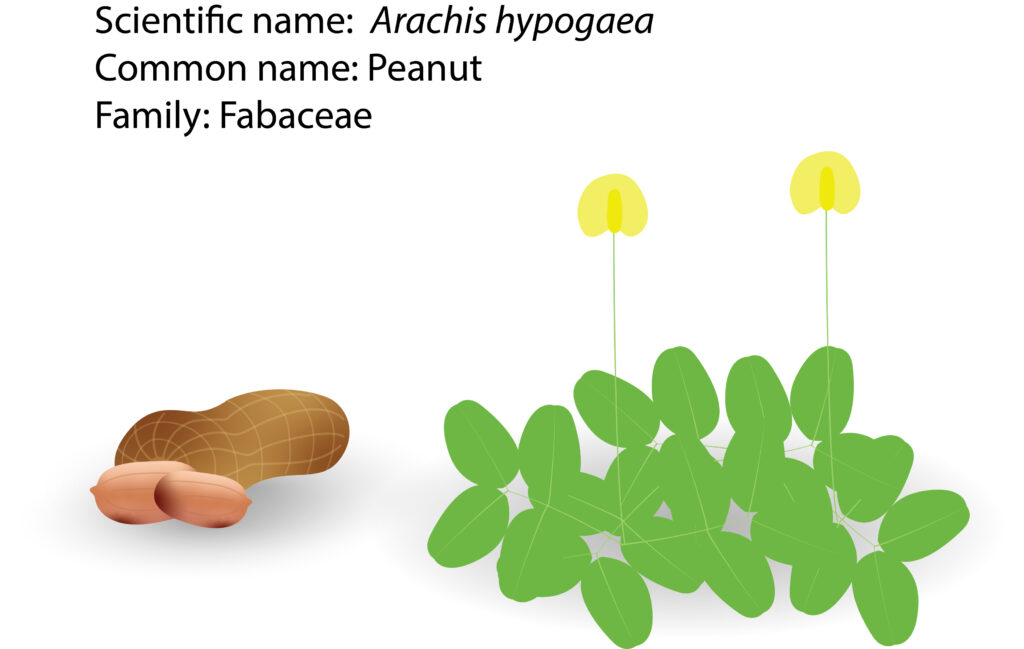

All species have pinnate leaves with a variable number of leaflets. The pea-like flowers are usually yellow and rather small. As the flower fades, the stalk (or ‘peg’) of the developing pod lengthens and grows down and into the soil, ripening its seeds beneath the surface. All species of this genus are unusual when compared to other legumes as they produce their fruit below the ground. Harvesting of the nuts is usually achieved by digging the whole plant, just as for potatoes.

Anyone can grow peanuts simply by purchasing raw peanuts from a health-food store and planting them just like beans, to which their cultivation requirements are very similar. The soil needs to be loose and open to allow the pegs to penetrate. They require a protected and sunny position and are quite frost-tender.

Arachis hypogaea

The species name comes from the Greek for ‘below the earth’, referring to the unique botanical feature of this plant. It is usually referred to as peanut, groundnut, earthnut, goober, pinder or monkey nut. Peanut is the third most important source of plant protein, which forms 11 % of the protein supply in the world. It is an annual that requires a long and warm growing season for the fruit to mature fully.

Peanut is a dicotyledonous plant. The species of this genus are diverse in their habitat, which includes grasslands, open patches of forest and temporarily flooded areas. There are thousands of peanut cultivars around the world. Certain cultivars groups are preferred for particular uses because of differences in flavor, oil content, size, shape and disease resistance. It grows to about 12 inches tall and has leaves with 4 leaflets as well as red-veined and yellow flowers.

The most popular cultivars are Spanish, Runner, Virginia and Valencia. Spanish peanuts are used mostly for peanut candy, salted nuts, and peanut butter. Most Runner cultivars are used to make peanut butter. Most peanuts marked in the shell are of the Virginia type, along with some Valencias selected for large size and the attractive appearance of the shell.

Nutritional value and downstream products

Peanut is a legume crop grown mainly for its edible oilseed crop in the world. Peanuts contain crude protein around 24 % to 36 % on a dry weight basis, which is second only to soybean (36 % to 51 %) in edible oil crops. Peanuts contain eight essential amino acids such as palmitic, oleic, linolenic, stearic, arachidic, eicosenoic, behenic, and lignoceric acids are rich in 80 % unsaturated and 20 % saturated fatty acids as well as other active compounds like vitamins, procyanidins, flavonoids, and resveratrol. Interest in the application of peanut proteins and other byproducts in food increases from time to time as it has high nutritional value and yield with a low starting price.

There are two types of peanut protein, which are water-soluble proteins that consist of around 10 % of the dry weight basis and salt-soluble proteins that contain 90 % of the dry weight. The salt-soluble proteins contain approximately 73 % arachin, 6 % conarachin I, 21 % conarachin II and some other minor components.

The conventional extraction methods include the press method (hot and cold pressing method), leaching process and alkali-soluble acid method. About 80 % to 90 % of the peanut oil can be extracted through the hot pressing method. However, most peanut protein will be denatured and the water-soluble proteins as well as some other functional compounds will be decreased due to high-temperature treatment.

The cold pressing process that involved 60 °C able to retain the nutritional components, but the yield of the oil is low. The leaching process is costly and more complicated among the extraction methods. The common extraction method is alkali-soluble acid precipitation method is usually used to prepare protein isolate, which can remove water-soluble sugar. Additionally, it also helps to remove starch, cellulose as well as other components.

Generally, there are three types of peanut oil, that are refined peanut oil, gourmet peanut oil and 100 % peanut oil. Refined peanut oil has been refined, bleached and deodorized. It is very low in saturated fats and is a popular oil for frying applications due to its high smoke point. Refined peanut oil is also non-allergenic as the processes removed the allergic protein component of the oil. It is the main type of oil utilized in major fast-food chains in the United States.

Furthermore, some of the gourmet peanut oil may be roasted, aromatic oil, which provides a Gourmet roasted peanut oil that is not refined and is considered specialty oil. However, it contains significant levels of vitamin E and phytosterols. Moreover, 100 % peanut oil is highly aromatic, but sometimes it is blended with other oils. This type of peanut oil is usually functioning as flavoring compounds, confections, sauces and baked goods as it has a strong roasted peanut flavor.

Peanuts have value-added products that have been developed with various applications in bakery, confectionery and the general consumer market. Apart from peanut oil and refined peanut oil, the raw peanuts can be roasted to make roasted peanuts or it can be processed into peanut flour or peanut milk. Roasted peanut is then blanched and sorted before grinding into a creamy texture then mix with sweeteners, salt as well as small amount of stabilizers to produce peanut butter. A peanut butter should contain a minimum 90 % of peanuts.

Peanut snacks (salted or unsalted) are consumed mainly in the Asian subcontinent. For most peanut products, the peanut skins are removed and discarded by a process known as blanching. The skin portion presents approximately 3 % of the total kernel mass. Unfortunately, its application in animal feed is limited by the bitter flavor and high levels of protein-binding components that are known as polyphenols. Peanut skin has been used in traditional Chinese medicine as an infusion or “tea” to treat chronic hemorrhages and bronchitis. In addition, the active compounds of peanut skins can be extracted as they consist of antioxidant, antimicrobial and anticancer activities.

Apart from their wide applications in the food industry, their health properties are well studied nowadays. Peanut oil is naturally trans-fat-free, cholesterol-free and low in saturated fats. It is proven that anti-inflammatory, anti-tumor and anti-cancerous activities.

Peanut flour

Peanut flour is a potential additive to increase the protein contents of various food commodities, especially baked goods. It is commonly used in confectionery products, seasoning blends, bakery mixes, frostings, fillings, cereal bars and nutritional bars. Peanut flour is made from raw peanuts which have been cleaned, blanched and electronically sorted to select the highest quality peanuts. The nuts are then roasted and naturally processed to obtain lower-fat peanut flour with a strong roasted peanut flavor.

Peanut flour has a high protein content of about 45 to 50 %, making it a good source of protein. It can be used as a flavoring agent as well as for coating meat products. Additionally, it is also used in other preparations like soup, cookies and curries due to its emulsifying properties. Peanut flour can be used for making composite flours with non-wheat cereals or to supplement wheat flour with protein-rich sources like legume flours. This can improve the nutritional value of bread in countries where wheat production is insufficient.

Peanut milk

Peanut milk is made from sludge produced by grinding one volume of raw peanuts with six volumes of water for thirty minutes. One of the earliest methods for preparing peanut milk is to mix the finely ground peanut flour with water. The drink has a protein, carbohydrate and vitamin content equivalent to that of animal milk. The sterilized product is stable for up to six months at room temperature. Its acceptability has been found to depend on the color of the product, absence of peanut flavor, taste and likeness to milk, and mouthfeel.

Peanut allergy

Food allergy is a common problem encountered by primary care physicians. It is estimated to affect 4 to 8 % of children and 1 to 2 % of adults and is considered a major cause of life-threatening hypersensitivity reactions. Commonly, there are 8 foods that are responsible for more than 90 % of food allergies. For instance, cow’s milk, egg, soy, wheat, peanut, tree nuts, fish and shellfish.

Peanut allergy was once rare, but it is now the most common cause of fatal food-allergic reactions. Peanut allergy is a potentially life-threatening condition that affects 1% to 3% of the Western world. It usually begins in early childhood and develops in early life, is rarely outgrown, and has no currently approved treatment. Peanut allergy is also the most common cause of food-related fatal anaphylaxis. Accidental reactions are common as peanuts can be hidden in various foods or contaminate meals in restaurants. Therefore, avoidance can be difficult as the labelling can be inadequate or misinterpreted by families or caregivers.

Parents of peanut-allergic children also experience high levels of stress, mainly due to the risk of death and constant dietary restrictions on their children. A typical history of a hypersensitivity reaction to peanuts following ingestion, in combination with a positive skin prick test or peanut specific immunoglobulin E (IgE), would point towards a diagnosis of peanut allergy. Typical symptoms include urticaria, angioedema, nausea, abdominal pain, vomiting, wheezing and breathlessness, occurring soon after ingestion.

Research has proved that many allergists recommend complete avoidance of all tree nuts in a child with a peanut allergy. This advice is supported by the possible risk of cross-contamination between various nuts and also problems with the labelling of food products. On the other hand, the avoidance of nut consumption in early life may be associated with an increased risk of development of new nut allergies. It is possible that the introduction of certain nuts (to which the child is not allergic) may prevent the development of further nut allergies and at the same time expand the repertoire of the diet of the child.

Postharvest disease and management

Entire plants are removed from the ground and formed into windrows, which are dried in the open air. After a specific time, peanuts are mechanically picked and brought to a processing facility where they are dried by a fan at about 35 degree Celsius to 10 % moisture. Peanuts are allowed to mature as determined by the internal surface color of the shell of a representative sample. During cleaning, dirt, stones, plant material, and other debris are removed by screens and blowers.

Peanuts are easily contaminated by Aspergillus flavus, a fungal species that can produce aflatoxin. The infection can occur during storage or transportation of peanuts. Peanut kernels act as a good substrate for mold growth when the moisture content, temperature and time are at optimum. Aflatoxin is a highly toxic and carcinogenic secondary metabolite of concern in food safety. The infection of the fungus can be induced by soil moisture stress during pod-filing when soil temperatures are near optimal for Aspergillus flavus.

Apart from that, oxidation of the lipid fraction of peanut meals is a major cause of deterioration in fatty peanuts due to a high degree of fatty acid unsaturation. Linoleic and linolenic acid are polyunsaturated fatty acids that are very susceptible to oxidation even under mild ambient conditions and are easily incorporated into the chain mechanism of lipid peroxidation that produces free and peroxy radicals.

Peanuts can also be stored under conditions that maintain moisture below 10%. Temperature should be maintained between 0 and 10 degree Celsius. If shelled, peanuts must be stored at a lower relative humidity to maintain low moisture content. Shelled peanuts can be stored for a maximum of 18 months compared to 24 months for in-shell peanuts.

Further reading:

Francisco, M. L. D., & Resurreccion, A. V. A. (2008). Functional components in peanuts. Critical reviews in food science and nutrition, 48(8), 715-746.

Kumar, S. J., Prasad, S. R., Banerjee, R., Agarwal, D. K., Kulkarni, K. S., & Ramesh, K. V. (2017). Green solvents and technologies for oil extraction from oilseeds. Chemistry Central Journal, 11, 1-7.

Natarajan, K. R. (1980). Peanut protein ingredients: preparation, properties, and food uses. Advances in food research, 26, 215-273.

Shewfelt, A. L., & YOUNG, C. Y. T. (1977). Storage stability of peanut‐based foods: a review. Journal of Food Science, 42(5), 1148-1152.

Sicherer, S. H., & Sampson, H. A. (2007). Peanut allergy: emerging concepts and approaches for an apparent epidemic. Journal of Allergy and Clinical Immunology, 120(3), 491-503.

Singh, B., & Singh, U. (1991). Peanut as a source of protein for human foods. Plant Foods for Human Nutrition, 41, 165-177.

Toomer, O. T. (2018). Nutritional chemistry of the peanut (Arachis hypogaea). Critical reviews in food science and nutrition, 58(17), 3042-3053.

Zhao, X., Chen, J., & Du, F. (2012). Potential use of peanut by-products in food processing: a review. Journal of food science and technology, 49, 521-529.